#inventory management in supply chain management

Explore tagged Tumblr posts

Text

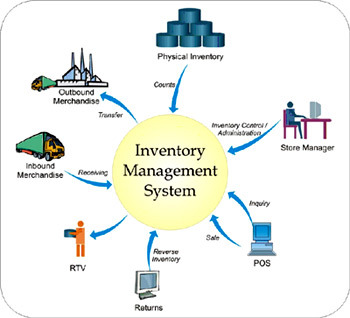

NextGen Invent is a cutting-edge inventory management in supply chain management. Seamlessly track, optimize, and control your inventory in real-time to streamline operations and boost efficiency. Upgrade to NextGen Invent for advanced inventory control and superior supply chain performance.

0 notes

Text

How Manufacturers Can Manage Growth with ERP

Introduction:

In the dynamic landscape of manufacturing, where growth is the ultimate goal, the ability to adapt and streamline operations is paramount. Enter ERP (Enterprise Resource Planning), a powerful solution that has revolutionized the way manufacturers operate. In this blog, we'll explore the significant role of ERP software for manufacturing industry and how it serves as a catalyst for sustainable growth. Whether you're in traditional manufacturing or a software development company, ERP solutions are key to optimizing processes and managing growth effectively.

Understanding the Essence of ERP Software for Manufacturing:

1. Efficiency Unleashed:

ERP system for manufacturing industry is designed to enhance operational efficiency by integrating various business processes. From order management and procurement to production planning and inventory control, ERP systems bring together disparate functions into a unified platform, eliminating silos and enhancing overall efficiency.

2. Real-time Insights:

One of the key advantages of ERP solutions is the ability to provide real-time insights into business operations. Manufacturers can make informed decisions based on up-to-date information, helping them respond swiftly to market changes, manage resources effectively, and capitalize on growth opportunities.

3. Scalability Matters:

As a manufacturer, scalability is a constant consideration. Whether you're a growing traditional manufacturing unit or a software development company expanding its operations, ERP systems offer scalability to accommodate changing needs. The modular nature of ERP solutions allows businesses to add or modify functionalities as they evolve.

4. Improved Collaboration:

Collaboration is the bedrock of successful manufacturing. ERP fosters better communication and collaboration by providing a centralized platform where employees across different departments can access and share information seamlessly. This not only enhances teamwork but also accelerates decision-making processes.

ERP Software for Manufacturing Industry: Tailoring Solutions for Success

1. Production Planning and Scheduling:

In the manufacturing realm, effective production planning and scheduling are crucial for meeting customer demands and maintaining optimal inventory levels. ERP systems facilitate streamlined production processes, enabling manufacturers to create realistic production schedules, allocate resources efficiently, and minimize downtime.

2. Supply Chain Management:

A well-integrated supply chain is essential for manufacturers. ERP solution for the manufacturing industry ensures smooth coordination between suppliers, manufacturers, and distributors. This results in better inventory management, reduced lead times, and ultimately, improved customer satisfaction.

3. Quality Control:

Maintaining consistent product quality is non-negotiable in manufacturing. ERP solutions provide tools for comprehensive quality control by enabling real-time monitoring of production processes, tracking defects, and ensuring adherence to quality standards. This not only boosts customer confidence but also reduces wastage and rework costs.

4. Financial Management:

The financial aspect is the backbone of any business. ERP systems for manufacturing offer robust financial management capabilities, including invoicing, expense tracking, and financial reporting. This level of financial control is invaluable for manufacturers looking to manage growth effectively and make strategic financial decisions.

ERP for Software Development Company: Tailoring Solutions to Tech

1. Project Management:

For software development companies, managing projects efficiently is critical. ERP solutions designed for the software development industry offer project management modules that help track project timelines, allocate resources effectively, and ensure that development projects stay on course.

2. Resource Planning:

In the software development realm, talent is a primary resource. ERP systems tailored for software companies facilitate resource planning by providing insights into employee availability, skills, and project commitments. This ensures optimal resource allocation for project success.

3. Version Control and Collaboration:

Version control and collaboration are key aspects of software development. ERP solutions for software companies include features that enable version control, code collaboration, and documentation management. This ensures that development teams work cohesively, leading to efficient project outcomes.

4. Compliance and Security:

In the software development industry, compliance and security are paramount. ERP systems for software companies often include modules that help manage compliance with industry standards and ensure data security. This is especially crucial in an era where data protection is a top priority.

Conclusion:

As manufacturers navigate the complexities of growth, ERP software emerges as an indispensable tool for success. Whether you're in traditional manufacturing or a software development company, the benefits of ERP systems are far-reaching. From enhancing operational efficiency and providing real-time insights to tailoring solutions for specific industry needs, ERP is the key to managing growth effectively. Embrace the power of ERP, and propel your manufacturing operations into a future of streamlined processes, informed decision-making, and sustained success.

#Go-To-Market#GTM#Supply-Chain-Management#Technology#India#ERP-India#ERP#Business-Solutions#Manufacturer#Engineering#Inventory-Management#ERP Software for Manufacturing Industry#ERP System for Manufacturing Industry#ERP for Software Development Company#ERP Solutions for Manufacturing

7 notes

·

View notes

Photo

Managing Inventory for Logistic: Strategies for Effective Supply Chain Management

Introduction

Good inventory management is vital for logistic firms to guarantee on-time and efficient supply chain management. This entails the careful monitoring, control, and optimization of stock levels to decrease expenses while fulfilling customer needs. The Best Logistic Company in India in this blog, discuss some techniques for successful inventory management that logistics companies can use to bolster their supply chain management.

Important techniques

1. Adopt a Just-in-Time (JIT) approach:

A Just-in-Time (JIT) method involves ordering products right when they are needed to meet customer orders, thereby eliminating the need for excessive stockpiling. This way, companies can minimize their inventory while still meeting consumer demands, thus cutting down on inventory carrying costs and freeing up space.

2. Use Forecasting Techniques:

Logistics companies can use forecasting techniques to predict customer demand and adjust inventory levels accordingly. This approach ensures that inventory levels are optimized to meet customer demand, reducing the risk of stockouts or excess inventory.

3. Utilize Technology:

Technology can help logistics companies manage their inventory more efficiently. Inventory management software can track inventory levels, forecast demand, and automate the reordering process.

4. Implement an ABC Analysis:

An ABC analysis categorizes inventory into three categories based on it’s value and usage.

Class A inventory is high-value and fast-moving,

Class B inventory is medium-value and medium-moving,

Class C inventory is low-value and slow-moving.

By categorizing inventory, logistics companies can prioritize inventory management efforts and allocate resources more effectively.

5. Adopt a Continuous Improvement Approach:

Continuous improvement involves constantly monitoring and optimizing inventory management processes. Logistics companies can use data analytics to track inventory performance, identify inefficiencies, and make data-driven decisions to improve inventory management.

Logistic companies can benefit greatly from implementing effective inventory management strategies. By adopting a JIT approach, using forecasting techniques, utilizing technology, implementing an ABC analysis, and adopting a continuous improvement approach, logistics companies can improve their supply chain management and provide better service to their customers.

#Inventory Management Strategies For Logistic And Supply Chain#Effective Inventory Control Methods For Supply Chain Management#3pl in India#Top logistic company in India#Best logistic company in India#3pl service provider

4 notes

·

View notes

Text

#Retail Inventory Management#Microservices Architecture#Event-Driven Architecture#AI in Retail#IoT Integration#Blockchain Transparency#Real-Time Data Processing#Supply Chain Optimization#Retail Technology#Inventory Optimization

0 notes

Text

Top 5 Supply Chain Management Software of 2025: Streamlining Business Operations

In the fast-paced world of business, efficient supply chain management is critical to success. As modern supply chains grow increasingly complex, businesses need powerful tools to streamline operations, reduce costs, and ensure smooth delivery. This is where Supply Chain Management (SCM) software comes in, offering businesses the ability to manage everything from procurement to delivery in a single platform.

Top SCM software options for 2025 include Coupa, Netstock, NetSuite, Zoho Inventory, and Infor.

Coupa stands out for its comprehensive cloud-native solutions that include procurement, inventory management, and supply chain design, powered by AI analytics and automation. It integrates easily with ERP systems like SAP and Oracle, though it may come with a learning curve.

Netstock is a go-to for small to mid-sized businesses, offering simplified inventory management and forecasting tools. It integrates well with ERPs like SAP and Microsoft Dynamics and excels in demand forecasting, though some users desire more advanced reporting features.

NetSuite, an Oracle product, is known for its robust capabilities in inventory and procurement management, especially for multinational businesses. It offers seamless integration with Oracle’s ecosystem but can be complex to set up.

Zoho Inventory is ideal for smaller businesses, particularly in e-commerce, due to its multi-channel order management and integration with platforms like Shopify and Amazon. It’s praised for ease of use, though some find it a bit pricey.

Infor offers a scalable solution with AI-driven supply chain optimization, real-time visibility, and predictive analytics, particularly beneficial for industries like manufacturing and healthcare. However, users have reported challenges with data accuracy and interface design.

Choosing the right SCM software is crucial for ensuring your supply chain runs efficiently and adapts to evolving business needs.

0 notes

Text

Supply Chain and Warehouse Management: The Backbone of Logistics in the UAE

The UAE's strategic position has solidified its role as a global logistics hub. In this competitive landscape, effective supply chain management UAE and efficient warehouse management are paramount for business success. From supply and chain management UAE, supply chain mgmt UAE, and SCM management UAE to chain of supply management UAE, companies across the Emirates understand the critical nature of optimized logistics. This includes supply chain management management UAE, management chain supply UAE, and and supply chain management UAE, covering everything from SCM supply UAE and inventory management UAE (inventory mgmt UAE) to the intricacies of inventory and inventory management UAE, inventory and management UAE, and avoiding the pitfalls of inventory mismanagement UAE.

Logistics companies UAE offer a spectrum of services, addressing the complexities of supply chain UAE, supply and chain UAE, supply & chain UAE, supply of chain UAE, supply chain chain UAE, supply chain supply chain UAE, supply chain and UAE, supply chain management logistics UAE, logistics chain management UAE, logistics SCM UAE, and logistics management and supply chain UAE. These services encompass inventory control UAE, material management UAE, inventory and control UAE, inventory and inventory control UAE, warehouse management UAE, inventory management system UAE, logistics management UAE, and inventory mgmt system UAE.

Warehousing management UAE is a cornerstone of logistics. Businesses utilize advanced systems like inventory stock management system UAE, logistics and management UAE, managed logistics UAE, logistics mgt UAE, warehouse management system UAE (WMS system UAE), 3pl logistics UAE, management warehouse system UAE, inventory monitoring system UAE, warehouse mgmt system UAE, and WHSE management system UAE. These systems facilitate seamless services and logistics UAE. Understanding supply chain what is UAE, the process in supply chain management UAE, and the process of SCM UAE is essential.

3 pl UAE (or 3p l UAE) providers are integral, offering integrated solutions encompassing logistics transport UAE, transportation and logistics UAE, and streamlined approaches like simply chain UAE. Effective warehouse logistics UAE, warehouse and logistics UAE, stock management UAE, inventory stock management UAE, inventory management stock UAE, and storehouse management UAE are crucial. Businesses must be aware of the kinds of logistics UAE and the importance of in stock management UAE. The relevance of supply chain management UAE is undeniable.

Modern solutions include WMS software UAE, catering to diverse logistics businesses UAE. Stock management system UAE, inventory tracking management UAE, supply chain management in e commerce UAE, system stock management UAE, and supply chain management in operations management UAE are all vital. Managing stocking and inventory UAE, logistics shipment UAE, and logistics and supply chains UAE, while ensuring in stock inventory UAE, are key. For e-commerce, the supply chain of e commerce UAE and understanding operations management and supply chain management UAE are paramount.

3pl warehouse UAE, warehouse management software UAE, warehouse stock management system UAE, warehouse inventory tracking system UAE, Inventory management systems for warehouse UAE, ERP warehouse management system UAE, warehouse management system for 3pl UAE, management warehouse system UAE, and logistics warehouse management system UAE form the complex landscape of logistics in the UAE.

#logistics#supply chain management#supply and chain management#supply chain mgmt#scm management#chain of supply management#supply chain management management#management chain supply#and supply chain management#scm supply#inventory management#inventory mgmt#inventory and inventory management#inventory and management#inventory mismanagement#logistics companies#supply chain#supply and chain#supply & chain#supply of chain#supply chain chain#supply chain supply chain#supply chain and#supply chain management logistics#logistics chain management#logistics scm#logistics management and supply chain#inventory control#material management#inventory and control

0 notes

Text

The key to improving warehouse efficiency in today’s fast-paced business world lies in warehouse modernization. Adopting an advanced management system is one of the most impactful steps in this process. A WMS helps streamline operations by automating essential tasks like inventory tracking, order processing, and real-time data reporting.

0 notes

Text

Artificial Intelligence at the Core of Modern Inventory Systems

AI in Inventory Management

1 note

·

View note

Text

AI in Supply Chain Market to be Worth $58.55 Billion by 2031

Meticulous Research®—a leading global market research company, published a research report titled, ‘AI in Supply Chain Market by Offering (Hardware, Software, Other), Technology (ML, NLP, RPA, Other), Deployment Mode, Application (Demand Forecasting, Other), End-use Industry (Manufacturing, Retail, F&B, Other) & Geography - Global Forecast to 2031’

According to this latest publication from Meticulous Research®, the AI in supply chain market is projected to reach $58.55 billion by 2031, at a CAGR of 40.4% from 2024 to 2031. The growth of the AI in supply chain market is driven by the increasing incorporation of artificial intelligence in supply chain operations and the rising need for greater visibility & transparency in supply chain processes. However, the high procurement & operating costs of AI-based supply chain solutions and the lack of supporting infrastructure restrain the growth of this market.

Furthermore, the growing demand for AI-based business automation solutions is expected to generate growth opportunities for the players operating in this market. However, performance issues in integrating data from multiple sources and data security & privacy concerns are major challenges impacting market growth. Additionally, the rising demand for cloud-based supply chain solutions is a prominent trend in the AI in supply chain market.

Based on offering, the AI in supply chain market is segmented into hardware, software, and services. In 2024, the hardware segment is expected to account for the largest share of 44.4% of the AI in supply chain market. The large market share of this segment is attributed to advancements in data center capabilities, the growing need for storage hardware due to increasing storage requirements for AI applications, the crucial need for constant connectivity in the supply chain operations, and the emphasis on product development and enhancement by manufacturers. For instance, in January 2023, Intel Corporation launched its 4th Gen Intel Xeon Scalable processors (code-named Sapphire Rapids), the Intel Xeon CPU Max Series (code-named Sapphire Rapids HBM), and the Intel Data Center GPU Max Series (code-named Ponte Vecchio). These new processors deliver significant improvements in data center performance, efficiency, security, and AI capabilities.

However, the software segment is expected to record the highest CAGR of 43.2% during the forecast period. This segment's growth is driven by the rising focus on product development and the enhancement of supply chain software and the benefits offered by supply chain software in facilitating supply chain visibility and centralized operations.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5064

Based on technology, the AI in supply chain market is segmented into machine learning, computer vision, natural language processing, context-aware computing, and robotic process automation. In 2024, the machine learning segment is expected to account for the largest share of 63.0% of the AI in supply chain market. The large market share of this segment is attributed to the advancements in data center capabilities, increasing deployment of machine learning solutions and its ability to perform tasks without relying on human input, and the rapid adoption of cloud-based technology across several industries. For instance, in June 2022, FedEx Corporation (U.S.) invested in FourKites, Inc. (U.S.), a supply chain visibility startup. This strategic collaboration allows FedEx to leverage its machine learning and AI capabilities with data from FedEx, enhancing its operational efficiency and visibility.

However, the robotic process automation segment is expected to record the highest CAGR of 42.9% during the forecast period. The growth of this segment is driven by the increased adoption of RPA across various industries and the rising demand for automating business processes to meet heightened customer expectations.

Based on deployment mode, the AI in supply chain market is segmented into cloud-based deployments and on-premise deployments. In 2024, the cloud-based deployments segment is expected to account for the larger share of 75.6% of the AI in supply chain market. The large market share of this segment is attributed to the increasing avenues for cloud-based deployments, the superior flexibility and affordability offered by cloud-based deployments, and the increasing adoption of cloud-based solutions by small & medium-sized enterprises.

Moreover, the cloud-based deployments segment is expected to record the highest CAGR during the forecast period. The rapid development of new security measures for cloud-based deployments is expected to drive this segment's growth in the coming years.

Based on application, the AI in supply chain market is segmented into demand forecasting, supply chain planning, warehouse management, fleet management, risk management, inventory management, predictive maintenance, real-time supply chain visibility, and other applications. In 2024, the demand forecasting segment is expected to account for the largest share of 25.2% of the AI in supply chain market. The large market share of this segment is attributed to the rising initiatives to integrate AI capabilities in supply chain solutions, dynamic changes in customer behaviors and expectations, and the rising need to achieve accuracy and resilience in the supply chain. For instance, in March 2023, Zionex, Inc. (South Korea), a prominent provider of advanced supply chain and integrated business planning platforms, launched PlanNEL Beta. This AI-powered SaaS platform is designed for demand forecasting and inventory optimization.

However, the real-time supply chain visibility segment is expected to record the highest CAGR during the forecast period. This segment's growth is driven by the rising integration of AI capabilities into supply chains to obtain real-time data on them.

Based on end-use industry, the AI in supply chain market is segmented into manufacturing, food and beverage, healthcare & pharmaceuticals, automotive, retail, building & construction, medical devices & consumables, aerospace & defense, and other end-use industries. In 2024, the manufacturing segment is expected to account for the largest share of 23.1% of the AI in supply chain market. The large market share of this segment is attributed to the increasing number of manufacturing companies, favorable initiatives to integrate artificial capabilities in the supply chain, and the increasing focus on achieving accuracy and resilience in the supply chain among manufacturers.

However, the retail segment is expected to record the highest CAGR of 47.8% during the forecast period. This segment's growth is driven by the rising integration of AI capabilities in the retail supply chain to forecast inventory and demand and retailers' growing focus on meeting consumer expectations.

Based on geography, the AI in supply chain market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2024, Asia-Pacific is expected to account for the largest share of 36.9% of the AI in supply chain market. The large market share of this region is attributed to the rapid pace of digitalization and modernization across industries, the advent of Industry 4.0, and the growing adoption of advanced technologies across various businesses.

Moreover, the Asia-Pacific region is projected to record the highest CAGR of 42.7% during the forecast period. This market's growth is driven by the proliferation of advanced supply chain solutions, the rising deployment of AI tools across the region, and efforts by major market players to implement AI technology across various sectors.

Key Players

Some of the key players operating in the AI in supply chain market are IBM Corporation (U.S.), SAP SE (Germany), Microsoft Corporation (U.S.), Google LLC (U.S.), Amazon Web Services, Inc. (U.S.), Intel Corporation (U.S.), NVIDIA Corporation (U.S.), Oracle Corporation (U.S.), C3.ai, Inc. (U.S.), Samsung SDS CO., Ltd. (South Korea), Coupa Software Inc. (U.S.), Micron Technology, Inc. (U.S.), Advanced Micro Devices, Inc. (U.S.), FedEx Corporation (U.S.), and Deutsche Post DHL Group (Germany).

Complete Report Here : https://www.meticulousresearch.com/product/ai-in-supply-chain-market-5064

Key questions answered in the report:

Which are the high-growth market segments based on offering, technology, deployment mode, application, and end-use industry?

What was the historical market for AI in supply chain?

What are the market forecasts and estimates for the period 2024–2031?

What are the major drivers, restraints, and opportunities in the AI in supply chain market?

Who are the major players, and what shares do they hold in the AI in supply chain market?

What is the competitive landscape like in the AI in supply chain market?

What are the recent developments in AI in supply chain market?

What are the different strategies adopted by the major players in AI in supply chain market?

What are the key geographic trends, and which are the high-growth countries?

Who are the local emerging players in the AI in supply chain market, and how do they compete with the other players?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#AI in Supply Chain Market#AI-powered Supply Chain#Demand Forecasting#Real-time Supply Chain Visibility#Supply Chain Planning#Inventory Management#Fleet Management#Warehouse Management

0 notes

Text

Advanced Delivery Management Software - ZenDMS

ZenDMS is a cutting-edge delivery management software designed to optimize and automate the entire delivery process. From order placement to last-mile delivery, ZenDMS simplifies logistics, ensuring accuracy, efficiency, and real-time transparency for businesses and their customers. Visit:www.zendms.app

#Top Supply Chain Software Providers#Leading Supply Chain Management Solutions#Best Logistics Software Companies#Top SCM Software Providers#Best Supply Chain Management Platforms#Leading Logistics and SCM Software#Top Supply Chain Technology Solutions#Best Supply Chain Optimization Software#Top Logistics Management Software Providers#Best Tools for Supply Chain Management#Top Supply Chain Analytics Platforms#Best Software for Supply Chain Efficiency#Top Inventory Management Software Providers#Best Vendors for Supply Chain Solutions

0 notes

Text

Why Choose Inwizards for Optimizing Inventory Management in Your Supply Chain?

Struggling to streamline inventory management in your supply chain?

Choose Inwizards for efficient, tech-driven solutions! Our expert team leverages cutting-edge tools like IoT, AI, and analytics to optimize inventory, reduce waste, and improve demand forecasting. With a tailored approach, we ensure real-time tracking and seamless integration with your systems. Boost your supply chain efficiency and gain a competitive edge with Inwizards. Let’s transform your operations today!

#inwizards software technology#software development service#Software development Company#Software Development Agency#Custom Software#inventory management#supply chain management#software developers#Software Development

0 notes

Text

NextGen Invent is a cutting-edge technology company specializing in innovative solutions for the future. Harnessing the power of AI and automation, NextGen Invent is shaping the next generation of inventions with its forward-thinking approach. Explore the possibilities with NextGen Invent today!

#ai development services#generative ai development services company in usa#inventory management in supply chain management

0 notes

Text

How Supply Chain Disruptions Affect Global Trade?

The article discusses the significant impact of supply chain disruptions on global trade, highlighting various causes such as natural disasters, geopolitical tensions, pandemics, economic downturns, and cyberattacks. These disruptions lead to increased costs, product shortages, and a reevaluation of supply chain strategies aimed at enhancing resilience. The COVID-19 pandemic served as a key example, revealing vulnerabilities in global supply chains. To mitigate these effects, businesses and governments can adopt strategies like diversification, effective inventory management, digital transformation, and fostering collaboration. Ultimately, understanding these challenges is crucial for maintaining a smooth flow of goods and supporting economic growth globally.

#supply chain management#global trade#disruption#pandemic#digital transformation#education#business#tradecompliance#inventory strategies

0 notes

Text

Simplifying Inventory Optimization for Supply Chain Success

Efficient inventory management is the backbone of a successful supply chain management system. Advanced inventory optimization techniques have emerged as powerful tools to balance supply and demand while minimizing costs. These techniques offer strategies that enhance inventory control and streamline operations for better outcomes.

The is a transformative approach to inventory planning. By analyzing factors such as demand variability, lead time, review period, supply compliance, and production or distribution lot sizes, it creates a tailored curve for each product and location. This method ensures that inventory levels are aligned with customer service goals, striking a balance between availability and cost-efficiency in supply chain management.

Managing inventory across multiple supply chain management levels can be daunting. Multi-echelon inventory optimization simplifies this by determining the right echelon for inventory deployment. This strategy distributes inventory optimally across the network, reducing costs while maintaining high service levels, thereby enhancing overall efficiency.

Another crucial approach is multi-product inventory optimization, which focuses on determining the ideal service level for each product at every location. By intelligently allocating inventory budgets, this method addresses variability in demand, setting lower service targets for volatile items and meeting overall service requirements within supply chain management.

Just-in-time availability is vital to avoid both stockouts and overstocking. Continuous replenishment orders ensure that inventory is replenished as needed, promoting a lean and responsive supply chain management strategy. This reduces excess holding costs and enhances operational efficiency.

Advanced simulations play a pivotal role in refining inventory strategies. These simulations identify the best production lot sizes, distribution frequencies, and hub-spoke models. They also assist in segmentation strategies, tailoring the supply chain management system to meet the unique requirements of different product categories and business models.

Accurate stock norms are the foundation of effective inventory planning. By integrating variables like demand patterns, lead times, and lot sizes, modern systems generate precise stock norms. These tools combine multi-echelon and product optimization strategies to identify the most efficient inventory deployment tactics for supply chain management. Inventory optimization has evolved into a strategic advantage for businesses. Leveraging tools like the Stock to Service Curve, multi-echelon optimization, and advanced simulations enables companies to build resilient and efficient supply chain management systems. By adopting these methods, businesses can improve service levels, minimize costs, and achieve sustainable growth in competitive markets.

0 notes

Text

#Demand Forecasting#Supply Chain Management#Retail#Inventory Optimization#Predictive Analytics#Azilen Technologies

0 notes

Text

Supply chain management and Warehouse management in logistics UAE

Supply Chain and Warehouse Management: The Backbone of Logistics in the UAE

The UAE's strategic position has solidified its role as a global logistics hub. In this competitive landscape, effective supply chain management UAE and efficient warehouse management are paramount for business success. From supply and chain management UAE, supply chain mgmt UAE, and SCM management UAE to chain of supply management UAE, companies across the Emirates understand the critical nature of optimized logistics. This includes supply chain management management UAE, management chain supply UAE, and and supply chain management UAE, covering everything from SCM supply UAE and inventory management UAE (inventory mgmt UAE) to the intricacies of inventory and inventory management UAE, inventory and management UAE, and avoiding the pitfalls of inventory mismanagement UAE.

Logistics companies UAE offer a spectrum of services, addressing the complexities of supply chain UAE, supply and chain UAE, supply & chain UAE, supply of chain UAE, supply chain chain UAE, supply chain supply chain UAE, supply chain and UAE, supply chain management logistics UAE, logistics chain management UAE, logistics SCM UAE, and logistics management and supply chain UAE. These services encompass inventory control UAE, material management UAE, inventory and control UAE, inventory and inventory control UAE, warehouse management UAE, inventory management system UAE, logistics management UAE, and inventory mgmt system UAE.

Warehousing management UAE is a cornerstone of logistics. Businesses utilize advanced systems like inventory stock management system UAE, logistics and management UAE, managed logistics UAE, logistics mgt UAE, warehouse management system UAE (WMS system UAE), 3pl logistics UAE, management warehouse system UAE, inventory monitoring system UAE, warehouse mgmt system UAE, and WHSE management system UAE. These systems facilitate seamless services and logistics UAE. Understanding supply chain what is UAE, the process in supply chain management UAE, and the process of SCM UAE is essential.

3 pl UAE (or 3p l UAE) providers are integral, offering integrated solutions encompassing logistics transport UAE, transportation and logistics UAE, and streamlined approaches like simply chain UAE. Effective warehouse logistics UAE, warehouse and logistics UAE, stock management UAE, inventory stock management UAE, inventory management stock UAE, and storehouse management UAE are crucial. Businesses must be aware of the kinds of logistics UAE and the importance of in stock management UAE. The relevance of supply chain management UAE is undeniable.

Modern solutions include WMS software UAE, catering to diverse logistics businesses UAE. Stock management system UAE, inventory tracking management UAE, supply chain management in e commerce UAE, system stock management UAE, and supply chain management in operations management UAE are all vital. Managing stocking and inventory UAE, logistics shipment UAE, and logistics and supply chains UAE, while ensuring in stock inventory UAE, are key. For e-commerce, the supply chain of e commerce UAE and understanding operations management and supply chain management UAE are paramount.

3pl warehouse UAE, warehouse management software UAE, warehouse stock management system UAE, warehouse inventory tracking system UAE, Inventory management systems for warehouse UAE, ERP warehouse management system UAE, warehouse management system for 3pl UAE, management warehouse system UAE, and logistics warehouse management system UAE form the complex landscape of logistics in the UAE.

#logistics#supply chain management#supply and chain management#supply chain mgmt#scm management#chain of supply management#supply chain management management#management chain supply#and supply chain management#scm supply#inventory management#inventory mgmt#inventory and inventory management#inventory and management#inventory mismanagement#logistics companies#supply chain#supply and chain#supply & chain#supply of chain#supply chain chain#supply chain supply chain#supply chain and#supply chain management logistics#logistics chain management#logistics scm#logistics management and supply chain#inventory control#material management#inventory and control

0 notes